The scaling process reduces the flowline and causes early failure of entire ESP system.

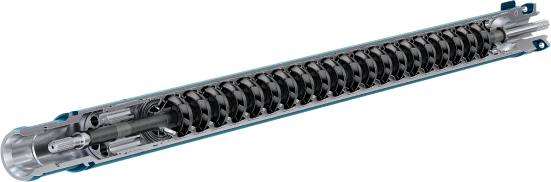

INP Hybrid series submersible pump is our response to high-corrosive fluids and mineral deposition (or scaling) on metallic surface. Especially in high water cut and high viscosity fluid.

Here you can see the scaling size on metal stages after 180 operation days in operation days in a scale-forming oil well

The diffuser inner surface and impeller flow paths are all covered with mineral deposits

So we designed and patented our solution – INP Hybrid with polymer stages.

The unique material delivers high acid- corrosion- gas- resistance together with a metal-like strength, it demonstrates steady operation at temperatures up to 270 °C

Ni-Resist diffuser flow paths

Polymer diffuser flow paths

In extensive field operation showed the following results:

- Triple scaling reduction or no scale build-up (depends on the configuration)

- Best solution for high-water cut. 1.5 times longer mean run-to-failure time in high-water-cut fluid

- Energy-efficient. 20% less power consumption and good balance on high rpm due to its light weight

- Reliable. No clogging, no plugging in fluid with high non-abrasive impurities

- Cost-saving. Requires much less or none chemical treatment for long service life

See field trials and application results in the Case studies library

| Pump series | OD | Nominal flow range | Max head per stage | Efficiency rate |

|---|---|---|---|---|

| 362 | 3.62 in | 189-943 bpd @60Hz | 26.5 ft | 36-59 % |

| 92 mm | 25- 125 m³/d @50Hz | 5.6 m | ||

| 406 | 4.06 in | 453-5585 bpd @60Hz | 26.9 ft | 44-69 % |

| 103 mm | 60-740 m³/d @50Hz | 5.7 m |

- Floating

- Semi-compression

- Compression

- Abrasive-resistant

- Corrosion-resistant

- Heat-resistant

to find the right solution