High Gas

Due to centrifugal forces that move the fluid up, there appear high- and low-pressure areas in the pump stages vanes during rotation.

The gas-phased bubbles, as they leave the heavier liquid phase, tend to accumulate on these low- pressure areas until they block the path of the entire impeller. This eventually causes the unexpected production interruptions and therefore lost revenue, increased field labor operations.

Our ESPs are tolerant up to 25% gas volume fractions (GVF) at the intake.

Pump + Disperser stages

UP TO 35 % GVF at the intake

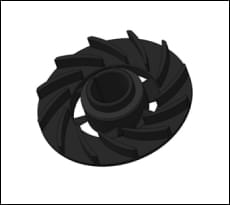

We developed specific stages, that can be set directly into your ESP pump without additional units and modules.

The “ribbed” impeller design on the top helps to homogenize the gas and liquid phases. This enables pump to effectively handle up to 35% GVF, while improving its overall lifting efficiency due to gas lift effect.

The disperser stages can be made of Ni-resist alloy (INP Standard line) or polymer composite, delivering all the advantages of using polymer stages (INP Hybrid line).

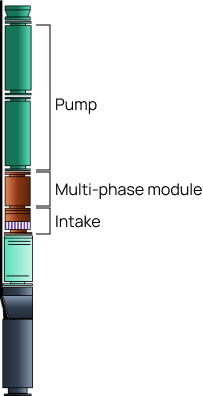

Pump + Multi-phase module

UP TO 55 % GVF at the intake

Multi-phase module is a centrifugal pump with dispersing stages, fitted between the ESP intake

and ESP itself.

It compresses liquid-gas mixture to the volume and density, required for efficient pump

operation, and homogenizes both liquid and gas phases, initiating gas lift effect in the pipes

above pump.

The multi-phase module facilitates pump steady operation reducing radial vibrations and improves pump overall lifting efficiency.

Pump + Gas separator

UP TO 60 % GVF at the intake

Gas separator is another gas-handling device, that physically separates free gas from fluid mixtures and disperses the gas through discharge ports into the wellbore annulus. It uses centrifugal force to separate gas from liquid before it enters the pump.

To provide high excellent shell resistance to erosion and corrosion, we developed unique auger vein and bearing unit design. It reduced wear rate down to 44% in comparison with standard gas separators.

Pump + Gas separator + Multi-phase module

UP TO 70 % GVF at the intake

This approach to gas management implies both gas separator and gas-dispersing multi-phase module

in one pump so you can not only achieve steady operation in a gassy oil well (up to 70% GVF),

but also improve lifting efficiency, since gas in the fluid initiates gas lift effect.

Multi-phase module smoothens some gas breakthroughs and uneven fluid flows.

Also using this system you can increase the input and output gas content without disruptions in ESP operation.

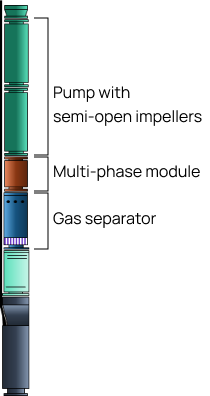

Pump with helicon-axial stages + Multi-phase module + Gas separator

UP TO 80 % GVF at the intake

For ultra-high GVF oil wells, beside gas separator and multi-phase module, we offer helicon-axial stages, that are installed right in the pump instead of its standard stages. Their special geometry serves to homogenize the gas and fluid phases.

The open-stage shape is designed to ease the flow of gas through the pump and reduce gas locking.

Tapered pump

Tapered pump is a series of two or more pumps with the same outside diameter - largest flow-rate pump at the bottom, and the smallest at the top.

Since the total volume decreases as the gas and oil mixture moves upwards through the pump due to gas compression, the largest pump is used to compress and mix gas and liquid mixture, and the smallest pump generates the head. This combination of two or more pumps allows to widen operating range.

to find the right solution