INP Hybrid line: 15% less power consumption

INP Hybrid line helps to save energy, that is proved by laboratory tests and field operation

Main three factors about INP Hybrid, that help to save energy:

1) As you know, all pump performance curves in catalogue are obtained with fresh water. So, having equal catalogue efficiency value with other ESPs, INP Hybrid shows better performance with oil well fluid (up to +5%). That’s because the hydraulic friction between polymer parts and the viscous fluid is far less than that with metallic parts.

2) Gas-resistant INP Hybrid (with disperser stages in its lower part) reliably handles with 60% GVF at the intake. Therefore, due to gas lift effect, it improves overall efficiency and reduces power consumption up to 15% (estimated by Gubkin University – the National university of Oil and Gas).

3) The inner space of metallic impellers usually reduces in size due to scaling and other fluid solids. But polymer flow paths of INP Hybrid stay clean, that is why its efficiency factor does not drop in the long run, so INP Hybrid operates with higher performance and saves energy up to 20% as compared with standard ESPs.

Laboratory tests

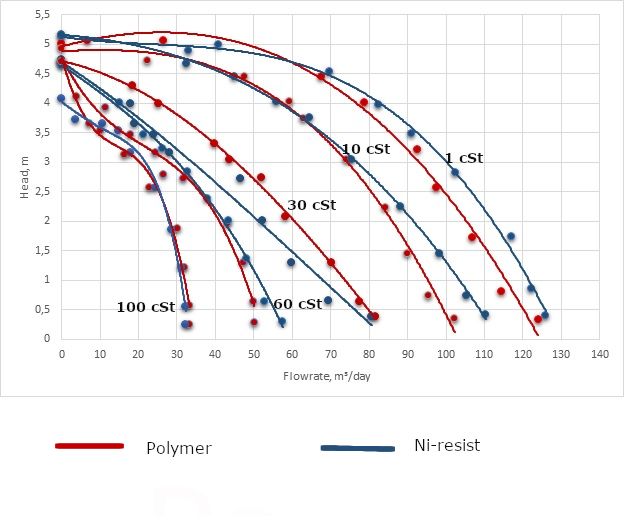

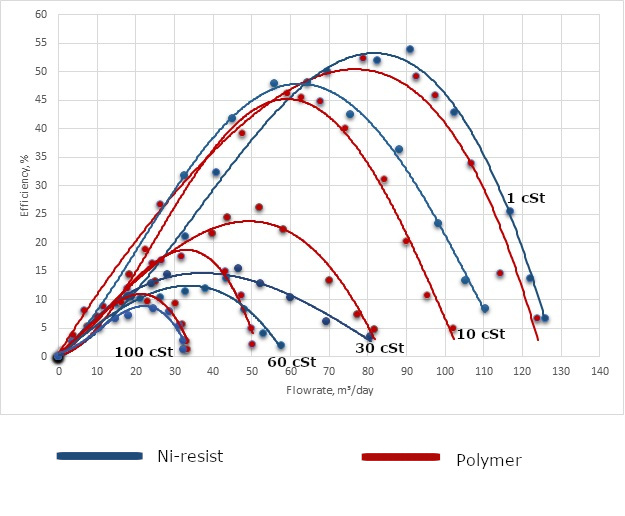

To confirm these facts we conducted laboratory tests and field trials. Together with Gubkin University (the National University of Oil and Gas) we assessed the influence of fluid viscosity on hydrodynamic performance of metallic and polymer stages. To obtain valid results we tested five stages under the following parameters:

Fluid temperature: +20°C

Fluid viscosity: 1 cSt; 10 cSt; 30 cSt; 60 cSt; 100 cSt

Viscosity alteration within ±2%

Fluid density: 1050 kg/m³

Results

Evaluation of laboratory tests

1) With the fluid viscosity more than 10 cSt the efficiency factor of metallic pump stage dropped lower (by 2…9%) than that of polymer stage.

2) As the viscosity increased from 1 cSt to 60 cSt, the dynamic head of metallic stage grows down, unlike the head of polymer stage.

3) With further viscosity increase up to 100 cSt the performance of metallic stages and polymer stages become equal.

The fluid viscosity in most Russian oilfields is within 30 – 80 cSt, so for them INP hybrid will be more efficient solution than ESPs with metallic stages.

Field test

We carried out field tests with Lukoil-Langepasneftegaz oil company to estimate the power consumption of INP Hybrid in comparison with standard ESPs (with metallic stages).

Equipment under test: 1) INP hybrid 2) ESP with metal stages

Test duration: 214 days

Operating environment: corrosive and scaling fluid without chemical treatment

Fluid viscosity: 32 cSt

Results:

INP hybrid demonstrated mean power cost reduction by 14.7% (3.6 kW per 1 m³ of extracted oil).

The other test was conducted at TNK-Nyagan (TNK-BP)

Equipment under test: 1) 10 INP hybrid systems 2) 10 standard ESPs with metal stages, equipped with gas-handling devices

Test duration: 266 days

Operating environment: gassy fluid with 45% GVF at the intake

Results:

INP hybrid demonstrated mean power cost reduction by 15.3% (3.7 kW per 1 m³ of extracted oil). This effect is achieved due to use of gas lift effect and non-stick properties of polymer impellers.