Non-stick properties test

Here we will compare the adhesive properties of polymer parts (INP Hybrid) and metal parts (any other ESP)

The process of salt depositing on internal parts of downhole equipment – scaling – is determined by many factors, including the sticking (or adhesive) properties of the equipment material.

We will consider wettability as a particular case of adhesion. Contact angle – the angle between solid and liquid surface. This measurement will provide us more quantitative approach to estimate sticking capability.

Since formation fluid is a conductive material, we will study the effect of voltage supply on pump stage materials (Ni-resist and polymer) sticking properties.

Testing equipment

Testing bench, power unit, photo camera.

Testing substance

Distilled water (dielectric) and normal saline (conductive fluid)

Testing samples

Ni-resist/ni-resist friction couple

Ni-resist/polymer friction couple

Testing procedure

1. We dried clean both friction couples

2. Isolated parts of the friction couple from each other with a tape and silicon sealer

3. Placed the friction couple on the testing bench and connected to the power adapter

4. Injected a drop of testing substance (at first - water, after that NS) on the friction couple so that the drop was right between the friction parts

5. Then we were applying voltage on the testing sample from 0 to 1V with the step of 0.2V and duration of 5 sec.

6. We made photo on every stage of the voltage change

7. Measured the contact angle

Test results

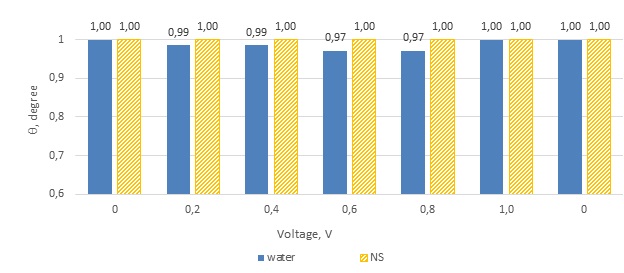

Change of contact angle for Ni-resist/ni-resist couple

Change of contact angle for Ni-resist/polymer couple

Conclusion

1. The contact angle of water drop for both testing samples did not change since the distilled water is a non-conductive liquid.

2. The contact angle of NS drop for ni-resist/ni-resist couple decreased by 23% as we increased voltage from 0 to 1V. That raises the risk of scaling.

3. The contact angle of NS drop for ni-resist/polymer couple did not change as we increased voltage from 0 to 1V. That means no scaling and stable operation even after mineral deposition.