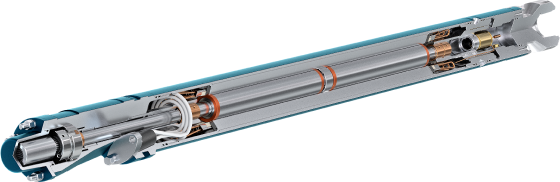

Generally submersible motor is the powerhouse of the entire ESP system.

The cable supplies power to the motor, than the motor converts electric power to mechanical power, transferring the torque via motor shaft.

According to customer’s requirements we provide an adaptor at the bottom of the motor to connect it

to downhole monitoring systems.

The motor casing can be plasma sprayed for excellent corrosion resistance.

The induction motors represent oil-filled three-phase two-pole electrical machines with squirrel cage and can be produced in one, two or three section design for basic or increased nominal voltage.

Unlike them permanent magnet motors design is based on permanent magnets, that interact with stator’s magnetic field. Therefore eliminating electrical losses in rotor and providing higher efficiency.

| Series | Motor OD | Rated power | Efficiency | Max temperature |

|---|---|---|---|---|

| 406 | 4.06 in | 22-286 HP @50Hz | 79.5 - 80% | Standard - 120°C Heat resistant - 150°C Ultra heat resistant - 170°C |

| 103 mm | 19-252 kW @60Hz | |||

| 461 | 4.61 in | 30-490 HP @50Hz | 84 - 85% | |

| 117 mm | 26-432 kW @60Hz | |||

| 512 | 5.12 in | 30-680 HP @50Hz | 82.5 - 85 % | |

| 130 mm | 26-600 kW @60Hz |

| Series | Motor OD | Rated power | Efficiency | Max temperature |

|---|---|---|---|---|

| 319 | 3.19 in | 27-136 HP @50Hz | 87 - 87.3% | Standard - 120°C Heat resistant - 150°C |

| 81 mm | 24-120 kW @60Hz | |||

| 461 | 4.61 in | 14-340 HP @50Hz | 89.4 – 93 % | |

| 117 mm | 12-300 kW @60Hz |

to find the right solution